Importance of Warehouse Lighting

01. Safety

Proper lighting reduces the risk of accidents by illuminating potential hazards, ensuring clear visibility of pathways, and highlighting obstructions.

02. Productivity

Comfortable lighting can reduce visual fatigue and improve workers’ work efficiency through good illumination uniformity and lower glare, making it easier to locate and handle goods.

03. Energy Efficiency

Different smart dimming methods in modern lighting solutions, such as PIR Sensor, Microwave Sensor, Daylight Sensor, DALI, Dimming, etc., help to enhance energy efficiency, significantly reduce energy consumption, and thereby save costs.

04. Accuracy

Proper light distribution, directing light precisely to areas that require illumination in different zones, ensures items are accurately picked, packed, and shipped accurately, reducing errors.

Lighting Effect Requirements for Warehouses

Adequate lighting in a warehouse is essential for ensuring safety, enhancing productivity, and improving the overall work environment. Here are the key lighting effect requirements:

Brightness

Depending on the specific tasks and areas within the warehouse, luminance levels should be adjusted. While general areas might require 20-50 lux, specialized tasks or inspection zones might necessitate upwards of 300 lux.

Uniformity

It’s vital to have consistent lighting across the warehouse to prevent the formation of shadows or dark spots, which can be hazardous.

Color Rendering Index (CRI)

A high CRI is crucial for accurate color perception, especially essential in areas where product quality and color differentiation are key.

Glare Control

Luminaires should be designed to minimize glare, ensuring worker comfort and reducing the risk of visual distractions.

Flicker-Free

To prevent eye strain and potential health issues, lighting should be stable without noticeable flickers.

Factors to Consider in Warehouse Lighting Design

Layout and Racking Configuration

The arrangement of aisles and shelves can influence the type and positioning of lights.

Type of Goods Stored

Warehouses storing perishable items or sensitive goods might require different lighting compared to those storing non-perishable items.

Operational Hours

24/7 operations might have different lighting needs compared to warehouses operating only during daylight hours.

Technology Integration

Consideration for smart lighting systems that can be integrated with warehouse management systems for optimal operation.

Lights Installation Requirements

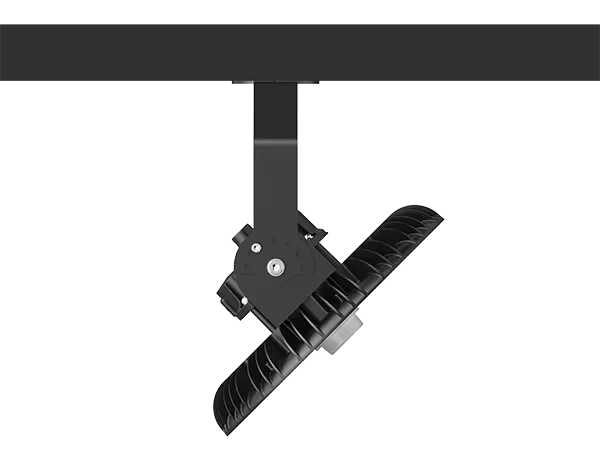

Mounting Method Options

01. Ceiling Mounting

In warehouses with relatively smooth ceilings, you can directly use the ceiling bracket for installation. The ceiling bracket can be divided into those with adjustable angles and those without, chosen based on actual lighting needs. This installation method is suitable for places with lower ceilings.

U-bracket ceiling mounting

The mounting method guarantees a stable and durable fixture, minimizing maintenance concerns.

±45° adjustable bracket ceiling mounting

The mounting method ensures precise light direction, catering to varied spatial needs.

02. Pendant Mounting

Hook Mounting

The installation environment in warehouses is often complex, with high mounting surfaces that may not always be flat. Therefore, the chain and hook method is a common and suitable installation approach.

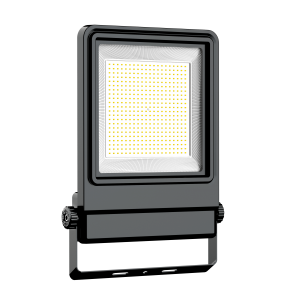

03. Wall Mounting

Wall Mounting

In some special situations, the wall mounting installation method is also required. Or as a supplement to warehouse lighting.

Mounting Height

The ideal height is influenced by the ceiling’s height and the nature of tasks. In warehouses with tall storage racks, lights are typically mounted between 20 to 40 feet. For specific task areas or lower ceilings, adjustments might be necessary.

Warehouse Lighting Solutions

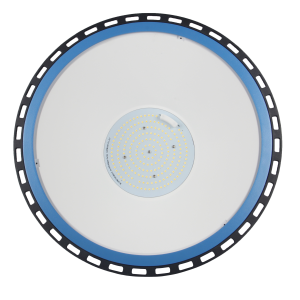

- Energy Efficiency: Our high bay lights utilize advanced LED technology, ensuring maximum luminosity with minimal energy consumption.

- Extended Lifespan: Crafted with durability in mind, our lights promise an extended operational lifespan, reducing replacement frequency.

- Uniform Illumination: Designed for optimal light spread, our high bay lights ensure consistent and shadow-free illumination across vast warehouse spaces.

- Safety Compliant: Meeting both national and international safety standards, our lights guarantee a risk-free and secure lighting environment.

- Eco-friendly Design: Complying with global environmental standards, our lights are mercury-free and emit minimal UV radiation, ensuring an eco-friendly footprint.

- Adaptable Mounting: Our high bay lights come with versatile mounting options, catering to varied warehouse ceiling heights and structures.

- Integrated Cooling: Featuring advanced heat dissipation mechanisms, our lights maintain optimal performance even in high-temperature environments.

- Glare Reduction: With precision-engineered optics, our lights minimize glare, ensuring comfort and safety for warehouse workers.

- Smart Control Integration: Our high bay lights are compatible with smart control systems, allowing for automated brightness adjustments and energy-saving modes.

- Robust Construction: Resistant to dust, moisture, and external impacts, our lights are built to withstand the challenging conditions of warehouses.